PF 04991532

GKA PF-04991532

(

S)-6-{3-cyclopentyl-2-[4-(trifluoromethyl)-1

H-imidazol-1-yl]propanamido}nicotinic acid

(S)-6-(3-Cyclopentyl-2-(4-(trifluoromethyl)-1H-imidazol-1-yl)propanamido)nicotinic Acid

(S)-6-(3-cyclopentyl-2-(4-(trifluoromethyl)-1H-imidazol-1-yl)propanamido)nicotinic acid

MW 396.36, MF C

18 H

19 F

3 N

4 O

3

CAS 1215197-37-7

3-Pyridinecarboxylic acid, 6-[[(2

S)-3-cyclopentyl-1-oxo-2-[4-(trifluoromethyl)-1

H-imidazol-1-yl]propyl]amino]-

http://www.biochemj.org/content/441/3/881

Type 2 diabetes mellitus (T2DM) is a rapidly expanding public

epidemic affecting over 300 million people worldwide. This disease is

characterized by elevated fasting plasma glucose (FPG), insulin

resistance, abnormally elevated hepatic glucose production (HGP), and

reduced glucose-stimulated insulin secretion (GSIS). Moreover, long-term

lack of glycemic control increases risk of complications from

neuropathic, microvascular, and macrovascular diseases.

The standard of care for T2DM is metformin followed by sulfonylureas,

dipeptidyl peptidase-4 (DPP-IV) inhibitors, and thiazolidinediones

(TZD) as second line oral therapies. As disease progression continues,

patients typically require injectable agents such as glucagon-like

peptide-1 (GLP-1) analogues and, ultimately, insulin to help maintain

glycemic control. Despite these current therapies, many patients still

remain unable to safely achieve and maintain tight glycemic control,

placing them at risk of diabetic complications and highlighting the need

for novel therapeutic options.

Glucokinase (hexokinase IV) continues to be a compelling target for

the treatment of type 2 diabetes given the wealth of supporting human

genetics data and numerous reports of robust clinical glucose lowering

in patients treated with small molecule allosteric activators. Recent

work has demonstrated the ability of hepatoselective activators to

deliver glucose lowering efficacy with minimal risk of hypoglycemia.

While orally administered agents require a considerable degree of

passive permeability to promote suitable exposures, there is no such

restriction on intravenously delivered drugs. Therefore, minimization of

membrane diffusion in the context of an intravenously agent should

ensure optimal hepatic targeting and therapeutic index.

Diabetes is a major public health concern because of its increasing

prevalence and associated health risks. The disease is characterized by

metabolic defects in the production and utilization of carbohydrates

which result in the failure to maintain appropriate blood glucose

levels. Two major forms of diabetes are recognized. Type I diabetes, or

insulin-dependent diabetes mellitus (IDDM), is the result of an absolute

deficiency of insulin. Type II diabetes, or non-insulin dependent

diabetes mellitus (NIDDM), often occurs with normal, or even elevated

levels of insulin and appears to be the result of the inability of

tissues and cells to respond appropriately to insulin. Aggressive

control of NIDDM with medication is essential; otherwise it can progress

into IDDM.

As blood glucose increases, it is transported into pancreatic beta

cells via a glucose transporter. Intracellular mammalian glucokinase

(GK) senses the rise in glucose and activates cellular glycolysis, i.e.

the conversion of glucose to glucose-6-phosphate, and subsequent insulin

release. Glucokinase is found principally in pancreatic β-cells and

liver parenchymal cells. Because transfer of glucose from the blood into

muscle and fatty tissue is insulin dependent, diabetics lack the

ability to utilize glucose adequately which leads to undesired

accumulation of blood glucose (hyperglycemia). Chronic hyperglycemia

leads to decreases in insulin secretion and contributes to increased

insulin resistance. Glucokinase also acts as a sensor in hepatic

parenchymal cells which induces glycogen synthesis, thus preventing the

release of glucose into the blood. The GK processes are thus critical

for the maintenance of whole body glucose homeostasis.

It is expected that an agent that activates cellular GK will

facilitate glucose-dependent secretion from pancreatic beta cells,

correct postprandial hyperglycemia, increase hepatic glucose utilization

and potentially inhibit hepatic glucose release. Consequently, a GK

activator may provide therapeutic treatment for NIDDM and associated

complications, inter alia, hyperglycemia, dyslipidemia, insulin

resistance syndrome, hyperinsulinemia, hypertension, and obesity.

Several drugs in five major categories, each acting by different

mechanisms, are available for treating hyperglycemia and subsequently,

NIDDM (Moller, D. E., “New drug targets for Type II diabetes and the

metabolic syndrome”

Nature 414; 821-827, (2001)): (A) Insulin

secretogogues, including sulphonyl-ureas (e.g., glipizide, glimepiride,

glyburide) and meglitinides (e.g., nateglidine and repaglinide) enhance

secretion of insulin by acting on the pancreatic beta-cells. While this

therapy can decrease blood glucose level, it has limited efficacy and

tolerability, causes weight gain and often induces hypoglycemia. (B)

Biguanides (e.g., metformin) are thought to act primarily by decreasing

hepatic glucose production. Biguanides often cause gastrointestinal

disturbances and lactic acidosis, further limiting their use. (C)

Inhibitors of alpha-glucosidase (e.g., acarbose) decrease intestinal

glucose absorption. These agents often cause gastrointestinal

disturbances. (D) Thiazolidinediones (e.g., pioglitazone, rosiglitazone)

act on a specific receptor (peroxisome proliferator-activated

receptor-gamma) in the liver, muscle and fat tissues. They regulate

lipid metabolism subsequently enhancing the response of these tissues to

the actions of insulin. Frequent use of these drugs may lead to weight

gain and may induce edema and anemia. (E) Insulin is used in more severe

cases, either alone or in combination with the above agents.

Ideally, an effective new treatment for NIDDM would meet the

following criteria: (a) it would not have significant side effects

including induction of hypoglycemia; (b) it would not cause weight gain;

(c) it would at least partially replace insulin by acting via

mechanism(s) that are independent from the actions of insulin; (d) it

would desirably be metabolically stable to allow less frequent usage;

and (e) it would be usable in combination with tolerable amounts of any

of the categories of drugs listed herein.

Substituted heteroaryls, particularly pyridones, have been implicated

in mediating GK and may play a significant role in the treatment of

NIDDM. For example, U.S. Patent publication No. 2006/0058353 and PCT

publication Nos. WO2007/043638, WO2007/043638, and WO2007/117995 recite

certain heterocyclic derivatives with utility for the treatment of

diabetes. Although investigations are on-going, there still exists a

need for a more effective and safe therapeutic treatment for diabetes,

particularly NIDDM.

PATENT

US 20100063063

http://www.google.com/patents/US20100063063

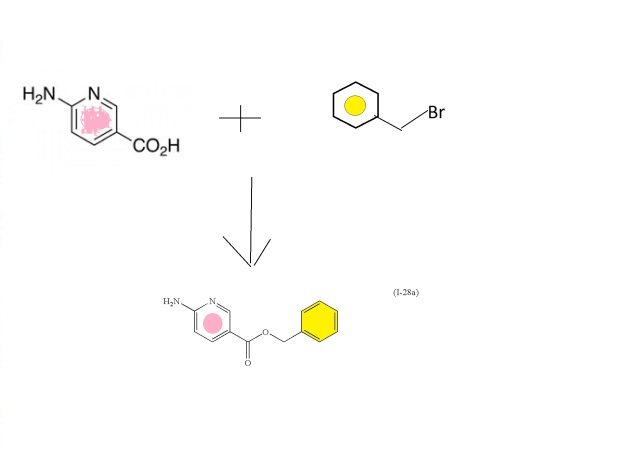

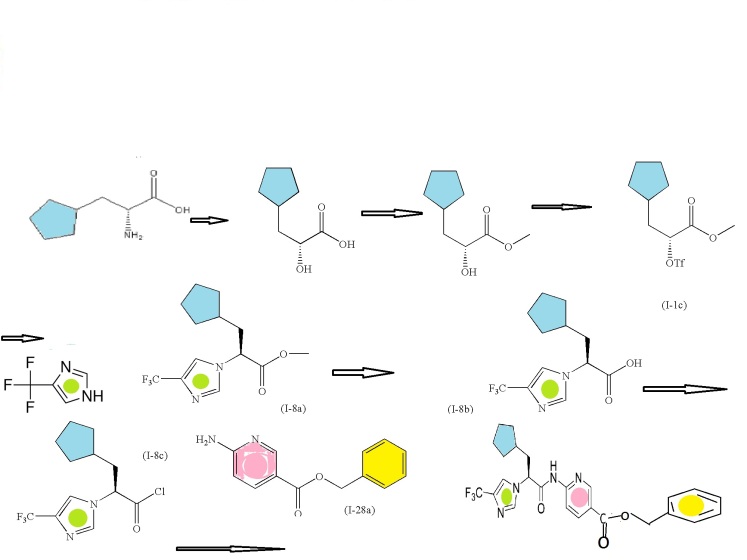

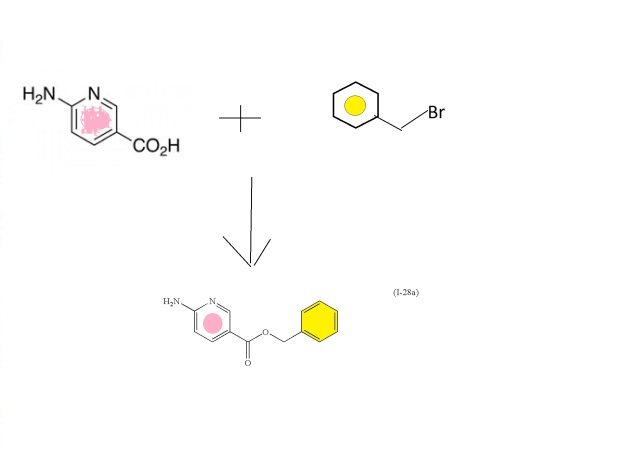

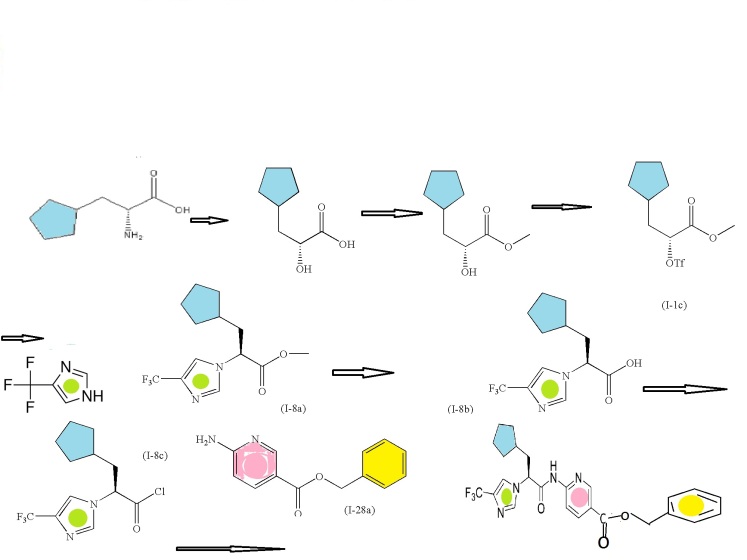

SYNTHESIS CONSTRUCTION

6-aminonicotinic acid

BENZYL BROMIDE

FIRST KEY INTERMEDIATE

SECOND SERIES FOR NEXT INTERMEDIATE

(R)-2-amino-3-cyclopentylpropanoic acid

(R)-methyl 3-cyclopentyl-2-hydroxypropanoic acid (I-1a)

(R)-methyl 3-cyclopentyl-2-hydroxypropanoate (I-1b)

Trifluoromethanesulfonic acid anhydride

(R)-methyl 3-cyclopentyl-2-(trifluoromethylsulfonyloxy)propanoate (I-1c)

CONDENSED WITH

4-Trifluoromethyl-1H-imidazole

TO GIVE PRODUCT SHOWN BELOW

(S)-methyl 3-cyclopentyl-2-(4-(trifluoromethyl)-1H-imidazol-1-yl)propanoate (I-8a)

(S)-3-cyclopentyl-2-(4-(trifluoromethyl)-1H-imidazol-1-yl)propanoic acid (I-8b)

CONVERTED TO ACID CHLORIDE, (S)-3-cyclopentyl-2-(4-(trifluoromethyl)-1H-imidazol-1-yl)propanoyl chloride (I-8c)

AND CONDENSED WITH

WILL GIVE BENZYL DERIVATIVE AS BELOW

THEN DEBENZYLATION TO FINAL PRODUCT

Intermediate: (R)-methyl 3-cyclopentyl-2-hydroxypropanoic acid (I-1a)

To a stirred solution of (R)-2-amino-3-cyclopentylpropanoic acid (5.0

grams; Chem-Impex International, Inc., Wood Dale, Ill.) and 1 M H

2SO

4 (45.1 mL) at 0° C., was added a solution of NaNO

2 (3.12 g) in H

2O

(15.6 mL) drop wise over 10 minutes. The reaction mixture was stirred

for 3 hours at 0° C., then for 2 hours at room temperature. The solution

was then extracted (3 times) with diethyl ether. The combined organic

extracts were dried over MgSO

4, filtered, and the filtrate concentrated to afford 2.36 g of (I-1a).

1H NMR (400 MHz, CDCl

3) δ 4.26-4.28 (1H), 1.99-2.07 (1H), 1.76-1.81 (4H), 1.60-1.62 (4H), 1.12-1.16 (2H); LCMS for C

8H

14O

3 m/z 157.1 (M−H)

−.

Intermediate: (R)-methyl 3-cyclopentyl-2-hydroxypropanoate (I-1b)

To a stirred solution of 2.36 g of (I-1a) in anhydrous methanol (15 mL) at room temperature was added SOCl

2(1.64

mL). The resulting mixture was heated at reflux for 2 hours. It was

then cooled and concentrated under reduced pressure. The residue was

partitioned between ethyl acetate and aqueous saturated NaHCO

3 solution.

The biphasic mixture was separated and the aqueous portion was

extracted with ethyl acetate. The combined extracts were dried over MgSO

4,

filtered, and the filtrate concentrated under reduced pressure. The

resulting residue was purified by flash column chromatography (silica

gel, heptanes/ethyl acetate) to afford 1.5 g of (I-1b) as a clear oil.

1H NMR (400 MHz, CDCl

3) δ 4.15-4.20 (1H), 3.77 (3H), 2.62-2.63 (1H), 1.97-2.05 (1H), 1.49-1.86 (8H), 1.06-1.17 (2H); LCMS for C

9H

16O

3 m/z 171.6 (M)

+. Intermediate (I-1b) can alternatively be prepared by the method described below.

A 0.2M solution of Li

2CuCl

4 was prepared as follows: Anhydrous CUCl

2 (26.9

g, 200 mol) and anhydrous LiCl (17.0 g, 400 mmol) were dissolved in THF

(1000 mL). The mixture required gentle heating to completely dissolve

the solids. After cooling the solution is ready for use.

A solution of Li

2CuCl

4 (0.2 M in THF, 125 mL,

25.0 mmol) was added slowly to a suspension of cyclopentylmagnesium

bromide (2 M in diethyl ether, 135 mL, 270 mmol; Aldrich Chemical

Company, Inc., Milwaukee, Wis.) and THF (500 mL) at −50° C. over 2-3

mins. The pale grey/brown suspension was then allowed to warm slowly to

−10° C. over 30 mins, by which time the color had developed to a dark

grey. The mixture was re-cooled to −78° C. and (R)-methyl

oxirane-2-carboxylate (25.0 g, 245 mmol; Aldrich Chemical Company, Inc.,

Milwaukee, Wis.) was added neat via syringe over 90 seconds. The

reaction was then stirred at −78° C. for 20 mins, before removing the

ice-bath and allowing to warm to approximately −50° C. over 30 mins.

Saturated NH

4Cl (aq, 700 mL) was then added and the mixture

stirred for 30 mins. The organic layer was collected and the aqueous

layer extracted with diethyl ether (2×250 mL). The combined organics

were washed with saturated NH

4Cl (aq, 350 mL), dried over MgSO

4,

and evaporated. Distillation of the crude residue (68-70° C. at 0.8

mbar) yielded 65-70% of (I-1b) as a pale yellow oil. A small amount of

less volatile material remained in the still pot.

1H NMR (400 MHz; CDCl

3): δ 4.17(1H), 3.76 (3H), 2.67 (1H), 2.01 (1H), 1.48-1.88 (8H), 1.11 (2H).

Intermediate: (R)-methyl 3-cyclopentyl-2-(trifluoromethylsulfonyloxy)propanoate (I-1c)

Intermediate: (R)-methyl 3-cyclopentyl-2-(trifluoromethylsulfonyloxy)propanoate (I-1c

Intermediate (I-1b) (6.37 g, 37.0 mmol) was dissolved in dry

dichloromethane (260 mL) and stirred under nitrogen in an ice bath.

2,6-Lutidine (9.0 mL, 77 mmol) was added. Trifluoromethanesulfonic acid

anhydride (11 mL, 65 mmol) in dry dichloromethane (75 mL) was added

dropwise. The reaction was stirred in the ice bath for 60 minutes,

concentrated under reduced pressure, and taken up in 1N HCl and methyl

t-butyl ether. The aqueous layer was separated, and the organic layer

was washed with additional 1N HCl to insure the removal of all the

lutidine. The combined organic layer was then washed with brine, dried

over sodium sulfate, filtered, concentrated under reduced pressure, and

dried under high vacuum to afford (I-1c) (11.3 g, 37 mmol, 100%), which

was used immediately without further purification;

1H NMR (400 MHz, CDCl

3) δ 5.10-5.14 (1H), 3.82 (3H), 2.02-2.12 (1H), 1.79-1.98 (4H), 1.51-1.66 (4H), 1.08-1.18 (2H).

Intermediate (I-1b) (6.37 g, 37.0 mmol) was dissolved in dry

dichloromethane (260 mL) and stirred under nitrogen in an ice bath.

2,6-Lutidine (9.0 mL, 77 mmol) was added. Trifluoromethanesulfonic acid

anhydride (11 mL, 65 mmol) in dry dichloromethane (75 mL) was added

dropwise. The reaction was stirred in the ice bath for 60 minutes,

concentrated under reduced pressure, and taken up in 1N HCl and methyl

t-butyl ether. The aqueous layer was separated, and the organic layer

was washed with additional 1N HCl to insure the removal of all the

lutidine. The combined organic layer was then washed with brine, dried

over sodium sulfate, filtered, concentrated under reduced pressure, and

dried under high vacuum to afford (I-1c) (11.3 g, 37 mmol, 100%), which

was used immediately without further purification;

1H NMR (400 MHz, CDCl

3) δ 5.10-5.14 (1H), 3.82 (3H), 2.02-2.12 (1H), 1.79-1.98 (4H), 1.51-1.66 (4H), 1.08-1.18 (2H)

Intermediate: (S)-methyl 3-cyclopentyl-2-(4-(trifluoromethyl)-1H-imidazol-1-yl)propanoate (I-8a)

4-Trifluoromethyl-1H-imidazole (5.0 g, 37.0 mmol; Apollo Scientific

Ltd., Bredbury, Cheshire, UK) was stirred in dry THF (180 mL) under

nitrogen at room temperature. Lithium hexamethyldisilazide (1M in THF,

33.4 mL, 33.4 mmol) was added dropwise via addition funnel. The mixture

was stirred at room temperature for 50 minutes and then chilled in an

ice bath. A solution of (I-1c) (11.3 g, 37 mmol) in dry THF (45 mL),

which had been chilled in an ice bath, was added in one portion. The

reaction was allowed to warm to room temperature, stirred for 2 hours,

quenched with saturated aqueous ammonium chloride solution (20 mL) and

allowed to stir overnight. The aqueous layer was separated, and the

organic layer was concentrated and then diluted with water and ethyl

acetate. The organic layer was washed in series with dilute aqueous

phosphoric acid, aqueous 10% potassium carbonate, and brine. The organic

layer was then dried over sodium sulfate, filtered, and concentrated

under reduced pressure to a brown oil. The crude material, containing

the undesired regioisomer as a small impurity, was purified by

chromatography on a 330 g pre-packed silica gel column, eluting with 10%

ethyl acetate/heptane, linear gradient to 70% ethyl acetate/heptane.

The product fractions were located by spotting on a silica TLC plate and

visualizing with KMnO

4 stain. TLC (1:1 ethyl

acetate/heptane, developed in potassium permanganate) located the pure

and mixed fractions. The clean product fractions were combined,

evaporated, and dried under high vacuum to afford (I-8a) as a clear oil

(6.61 g, 22.4 mmol, 67%).

1H NMR (400 MHz, CDCl

3) δ 7.57 (1H), 7.38 (1H), 4.71-4.74 (1H), 3.76 (3H), 2.01-2.14 (2H), 1.45-1.79 (7H), 1.03-1.18 (2H); m/z 291.4 (M+H)

+.

Intermediate: (S)-3-cyclopentyl-2-(4-(trifluoromethyl)-1H-imidazol-1-yl)propanoic acid (I-8b

6N HCl (140 mL) was added to (I-8a) (6.61 g, 22.4 mmol) and the

mixture was warmed to 95° C. for 16 hours and then allowed to cool.

Solid potassium carbonate (58 g) was added in portions to bring the pH

to about 4. A precipitate crashed out. Ethyl acetate was added, and the

mixture was stirred until everything dissolved. The aqueous layer was

extracted once with ethyl acetate. The combined organics were washed

with brine, dried over sodium sulfate, filtered, concentrated under

reduced pressure, and dried under high vacuum to afford (I-8b) as a

clear glass (6.15 g, 21.9 mmol, 98%).

1H NMR (400 MHz, CDCl

3) δ 7.73 (1H), 7.34 (1H), 6.85-7.15 (1H), 4.66-4.70 (1H), 1.98-2.17 (2H), 1.41-1.75 (7H), 1.01-1.19 (2H); m/z 277.4 (M+H)

+.

Intermediate: (S)-3-cyclopentyl-2-(4-(trifluoromethyl)-1H-imidazol-1-yl)propanoyl chloride (I-8c)

To a suspension of intermediate (I-8b) (0.25 g, 0.9 mmol) in

dichloromethane (5 mL) was added oxalyl chloride (0.35 g, 2.7 mmol) and

N,N-dimethylformamide (1 drop) at room temperature. The mixture was

stirred for 2 hours at room temperature. The reaction mixture was

concentrated in vacuo, and the residue was chased with dichloromethane

two times and concentrated in vacuo to afford (I-8c) (0.27 g, 100%) as

an oil, which was used in the next step directly.

Intermediate: (S)-6-(3-cyclopentyl-2-(4-(trifluoromethyl)-1H-imidazol-1-yl)propanamido) nicotinoyl chloride (I-21a)

-

Thionyl chloride (225 mg, 1.89 mmol) was added

to a solution of the compound of Example 48 (150 mg, 0.387 mmol) in

dichloromethane (1.5 mL) and the reaction stirred at room temperature

for 1 hour. LCMS of an aliquot in methanol showed ˜67% methyl ester. To

the reaction mixture was added another 25 uL of thionyl chloride and

this was stirred at room temp for another 30 minutes. Solvents were

evaporated to afford 157 mg (100%) of (I-21a) as a grayish-white solid.

LCMS in methanol to generate the methyl ester gave m/z 395.9 (M+H)+.

(I-8b

Intermediate: (S)-3-cyclopentyl-2-(4-(trifluoromethyl)-1H-imidazol-1-yl)propanoic acid (I-8b)

6N HCl (140 mL) was added to (I-8a) (6.61 g, 22.4 mmol) and the

mixture was warmed to 95° C. for 16 hours and then allowed to cool.

Solid potassium carbonate (58 g) was added in portions to bring the pH

to about 4. A precipitate crashed out. Ethyl acetate was added, and the

mixture was stirred until everything dissolved. The aqueous layer was

extracted once with ethyl acetate. The combined organics were washed

with brine, dried over sodium sulfate, filtered, concentrated under

reduced pressure, and dried under high vacuum to afford (I-8b) as a

clear glass (6.15 g, 21.9 mmol, 98%).

1H NMR (400 MHz, CDCl

3) δ 7.73 (1H), 7.34 (1H), 6.85-7.15 (1H), 4.66-4.70 (1H), 1.98-2.17 (2H), 1.41-1.75 (7H), 1.01-1.19 (2H); m/z 277.4 (M+H)

+.

(I-28a

Intermediate: benzyl 6-aminonicotinate (I-28a)

To a stirred suspension of 6-aminonicotinic acid (100 g, 0.72 mol;

Aldrich Chemical Company, Inc., Milwaukee, Wis.) in

N,N-dimethylformamide (700 mL) with brisk mechanical stirring was added

potassium carbonate (150 g, 1.08 mol) and the reaction was stirred for

10 min before the portionwise addition of benzyl bromide (95 mL, 0.80

mol). The reaction was stirred at room temperature overnight, then the

solids were filtered off and washed thoroughly with ethyl acetate, and

the solvent was removed under vacuum. The filter cake was dissolved in

water and extracted with ethyl acetate. The residue after evaporation of

N,N-dimethylformamide was combined with the ethyl acetate extracts

(total volume 2 L of ethyl acetate) and the combined organic extracts

washed with brine (5×500 mL), dried (MgSO

4) and the solvent

removed under reduced pressure. The crude product was refluxed with 1:1

diethyl ether:hexane for 30 min then the solids filtered off (warm),

washed with diethyl ether:hexane (1:1), and dried. This solid was

precipitated from hot toluene (hot filtration required to remove

dibenzylated material) and dried to afford (I-28a) (107.2 g, 65%) as an

off-white solid;

1H NMR (DMSO-d

6): δ 8.50 (1H), 7.82 (1H), 7.34-7.29 (5H), 6.84 (2H), 6.43 (1H), 5.23 (2H); m/z 229.4 (M+H)

+.

Example 47

(S)-benzyl 6-(3-cyclopentyl-2-(4-(trifluoromethyl)-1H-imidazol-1-yl)propanamido)nicotinate

Formula (1A-4) wherein R

4 is

To Intermediate (I-8b) (16.28 g, 59.8 mmol) stirring in dry

dichloromethane (400 mL) at room temperature under nitrogen was added 2

drops of DMF. Oxalyl chloride (11 mL, 130 mmol) was added dropwise.

After the bubbling subsided the reaction was left stirring for 90

minutes and then concentrated under reduced pressure. Two successive

portions of 1,2-dichloroethane were added and evaporated to remove all

excess oxalyl chloride. The crude acid chloride was taken up in

dichloromethane (150 mL) and stirred at room temperature. Intermediate

(I-28a) (14.3 g, 62.5 mmol) and pyridine (10 mL, 130 mmol) were stirred

in 400 mL dry dichloromethane. This was added to the acid chloride

solution, using another 50 mL dry dichloromethane to complete the

transfer. The mixture was left stirring at room temperature under

nitrogen for 18 hours. The reaction was diluted with dichloromethane and

water, and 1M aqueous phosphoric acid was added. The organic layer was

separated and washed sequentially with dilute aqueous potassium

carbonate, and brine. This was then dried over sodium sulfate, filtered,

and concentrated under reduced pressure to a glass, which was taken up

in hot ethyl acetate and stirred at room temperature. A precipitate

appeared at about 30 minutes. The mixture was stirred for 16 hours and

then filtered. The precipitate was washed with ethyl acetate and then

diethyl ether and dried under high vacuum at 60° C. to afford the title

compound as a white solid (17.8 g, 36.6 mmol, 61%). The mother liquor

was evaporated and purified by silica gel chromatography on a 120 g

pre-packed column, eluting with 40% ethyl acetate/heptane. The product

fractions were combined, concentrated under reduced pressure, dried

under high vacuum to a glass, and converted as previously described to

additional product (3.5 g, 7.2 mmol, 12%, total yield 73%).

1H NMR (400 MHz, DMSO-d

6)

δ 11.50 (1H), 8.87-8.88 (1H), 8.29-8.32 (1H), 8.12-8.14 (1H), 7.93-7.94

(2H), 7.39-7.46 (2H), 7.30-7.37 (3H), 5.32 (2H), 5.21-5.25 (1H),

2.06-2.19 (2H), 1.26-1.63 (8H), 1.01-1.06 (1H); m/z 487.5 (M+H)

+.

Example 48

(S)-6-(3-cyclopentyl-2-(4-(trifluoromethyl)-1H-imidazol-1-yl)propanamido)nicotinic acid

Formula (1A-4) wherein R

4 is

The compound of Example 47 (4.07 g, 8.35 mmol) was added to a 500 mL

Parr bottle, followed by ethyl acetate (50 mL) and ethanol (100 mL). The

mixture was warmed until all of the solid dissolved, and then cooled to

room temperature. 10% Pd/C (450 mg) was added, and the mixture was

shaken under 50 psi hydrogen for 90 minutes. The reaction was filtered

through a microfiber filter. The filtrate was concentrated under reduced

pressure and dried under high vacuum at 50° C. to afford product as a

glassy solid (3.0 g, 7.75 mmol, 90.6%). The glassy solid was stirred

overnight in diethyl ether. The white solid precipitate was filtered,

washed with diethyl ether, suction dried, and dried under high vacuum at

50° C. to afford the title compound as a white solid.

1H NMR (400 MHz, DMSO-d6)

δ 13.10-13.25 (1H), 11.44 (1H), 8.83 (1H), 8.23-8.26 (1H), 8.09-8.12

(1H), 7.94-7.95 (2H), 5.22-5.26 (1H), 2.06-2.17 (2H), 1.29-1.64 (8H),

1.04-1.07 (1H);

m/z 397.3 (M+H)+.

THIS NMR IS FROM SUPPORTING INFO OF A JOURNAL

PAPER

PAPER

Organic Process Research & Development (2012), 16(10), 1635-1645

http://pubs.acs.org/doi/abs/10.1021/op300194c

This work describes the process

development and manufacture of early-stage clinical supplies of a

hepatoselective glucokinase activator, a potential therapy for type 2

diabetes mellitus. Critical issues centered on challenges associated

with the synthesis of intermediates and API bearing a particularly

racemization-prone α-aryl carboxylate functionality. In particular, a

T3P-mediated amidation process was optimized for the coupling of a

racemization-prone acid substrate and a relatively non-nucleophilic

amine. Furthermore, an unusually hydrolytically-labile amide in the API

also complicated the synthesis and isolation of drug substance. The

evolution of the process over multiple campaigns is presented, resulting

in the preparation of over 110 kg of glucokinase activator.

(S)-6-(3-Cyclopentyl-2-(4-(trifluoromethyl)-1H-imidazol-1-yl)propanamido)nicotinic Acid (1)

Pressure Hydrogenation

1 (89% yield) as a white solid:

mp 187–189 °C;

1H NMR (400 MHz, d6-DMSO)

δ 13.23 (s, 1H), 11.49 (s, 1H), 8.86 (dd, J = 0.4, 2.4 Hz, 1H), 8.27

(dd, J = 2.4, 8.8 Hz, 1H), 8.13 (d, J = 8.8 Hz, 1H), 7.97–7.99 (m, 2H),

5.27 (dd, J = 5.6, 10.0 Hz, 1H), 2.20 (ddd, J = 6.0, 10.0, 14.0, 1H),

2.10 (ddd, J = 5.6, 8.4, 14.0, 1H), 1.27–1.69 (m, 8H), 1.03–1.12 (m,

1H);

13C NMR (100 MHz, d6-DMSO) δ 168.8, 165.7, 154.3, 149.7, 139.6, 138.8, 129.9 (q, JCF = 38 Hz), 122.6, 122.0 (q, JCF = 265 Hz), 120.0 (q, JCF = 4 Hz), 112.8, 60.0, 37.6, 36.2, 32.0, 30.8, 24.6, 24.4;

19F NMR (376 MHz, d6-DMSO) δ −60.7.

HRMS-ESI m/z: [M + H]+ calcd for C18H19F3N4O3, 397.1482; found, 397.1481.

Achiral HPLC: rt 4.6 min. Chiral SFC: rt 4.1 min (1), 3.1 min (ent-1).

PAPER

Journal of Medicinal Chemistry (2012), 55(3), 1318-1333

http://pubs.acs.org/doi/abs/10.1021/jm2014887

Glucokinase is a key regulator of

glucose homeostasis, and small molecule allosteric activators of this

enzyme represent a promising opportunity for the treatment of type 2

diabetes. Systemically acting glucokinase activators (liver and

pancreas) have been reported to be efficacious but in many cases present

hypoglycaemia risk due to activation of the enzyme at low glucose

levels in the pancreas, leading to inappropriately excessive insulin

secretion. It was therefore postulated that a liver selective activator

may offer effective glycemic control with reduced hypoglycemia risk.

Herein, we report structure–activity studies on a carboxylic acid

containing series of glucokinase activators with preferential activity

in hepatocytes versus pancreatic β-cells. These activators were designed

to have low passive permeability thereby minimizing distribution into

extrahepatic tissues; concurrently, they were also optimized as

substrates for active liver uptake via members of the organic anion

transporting polypeptide (OATP) family. These studies lead to the

identification of 19 as a potent glucokinase activator with a

greater than 50-fold liver-to-pancreas ratio of tissue distribution in

rodent and non-rodent species. In preclinical diabetic animals, 19

was found to robustly lower fasting and postprandial glucose with no

hypoglycemia, leading to its selection as a clinical development

candidate for treating type 2 diabetes.

(S)-6-(3-Cyclopentyl-2-(4-(trifluoromethyl)-1H-imidazol-1-yl)propanamido)nicotinic Acid (19)

afford 19 as a white solid (3.22 g, 71%).

1H NMR (400 MHz, DMSO-d6) δ 11.47 (s, 1H), 8.86 (d, J = 1.95 Hz, 1H), 8.27 (dd, J = 2.24, 8.68 Hz, 1H), 8.13 (d, J = 8.78 Hz, 1H), 7.97 (d, J = 4.88 Hz, 2H), 5.27 (dd, J = 5.37, 9.66 Hz, 1H), 2.04–2.26 (m, 2H), 1.38–1.72 (m, 7H), 1.26–1.37 (m, 1H), 1.08 (td, J = 7.88, 11.75 Hz, 1H);

LCMS m/z 397.5 (M + H)+.

HPLC purity (method A): tR = 7.690 min, 100%.

PAPER

Bioorganic & Medicinal Chemistry Letters (2013), 23(24), 6588-6592

http://www.sciencedirect.com/science/article/pii/S0960894X13012638

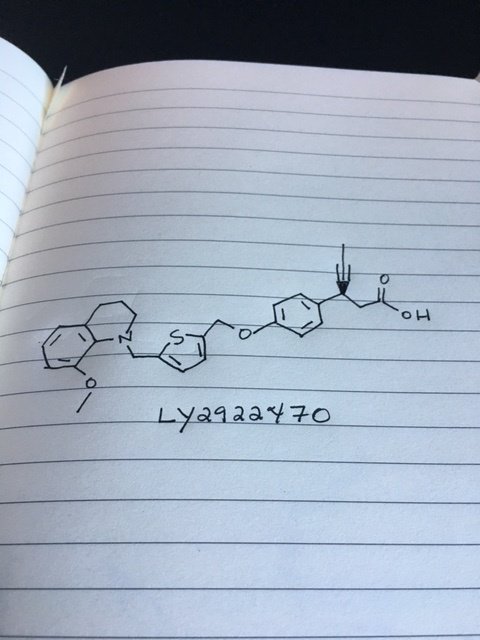

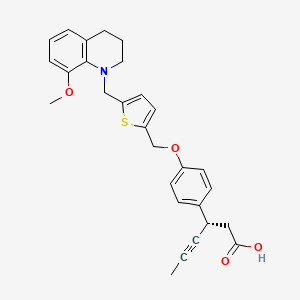

Figure 1.

Structure of Hepatoselective GKA PF-04991532 (1).

References

Drug Metabolism & Disposition (2015), 43(2), 190-198

PLoS One (2014), 9(5), e97139/1-e97139/9,

Journal of Biological Chemistry (2012), 287(17), 13598-13610

Drug Discovery Today (2012), 17(9-10), 528-529

Biochemical Journal (2012), 441(3), 881-887.

///////////

Figure 1. Representative structures of glucokinase activators.

DRUG APPROVALS BY DR ANTHONY MELVIN CRASTO …..FOR BLOG HOME CLICK HERE

DRUG APPROVALS BY DR ANTHONY MELVIN CRASTO …..FOR BLOG HOME CLICK HERE amcrasto@gmail.com

amcrasto@gmail.com