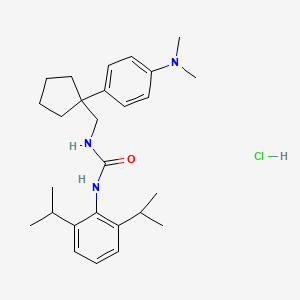

N-(2,6-bis(1-methylethyl)phenyl)-N'-((1-(4-(dimethylamino)phenyl)cyclopentyl) methyl)urea hydrochloride

N-(2,6-BIS(l-METHYLETHYL)PHENYL)-N'-((l-(4- (DIMETHYLAMINO)PHENYL)CYCLOPENTYL)METHYL)UREA

ATR-101; ATR 101; ATR101; PD132301-2; PD-132301-2; PD 132301-2; PD132301; PD-132301; PD 132301.

IUPAC/Chemical Name: 1-(2,6-diisopropylphenyl)-3-((1-(4-(dimethylamino)phenyl)cyclopentyl)methyl)urea hydrochloride

ATR-101 HCl

CAS#: 133825-81-7 (ATR-101 HCl); 133825-80-6 (ATR-101).

| Molecular Formula: | C27H40ClN3O |

|---|---|

| Molecular Weight: | 458.079 g/mol |

| The Regents Of The University Of Michigan, Atterocor, Inc. |

ATR-101, also known as PD-132301 (a free base) or PD-132301-2 (a HCl salt), is in clinical development for the treatment of adrenocortical carcinoma (ACC). ATR-101 is a selective inhibitor of ACAT1 (acyl coenzyme A:cholesterol acyltransferase). ACAT1 catalyzes cholesterol ester formation and, in the adrenals, is particularly important in creating a reservoir of substrate for steroid biosynthesis. ATR-101 is uniquely distributed to adrenal tissues and inhibition of adrenal ACAT1 by ATR-101 disrupts steroidogenesis and leads to selective apoptosis of steroid producing adrenocortical-derived cells. Similar effects have been seen in the human ACC cell line, H295R. ATR-101 has shown pre-clinical efficacy in H295R xenograft mouse models. ACC is an ultra-rare malignancy, occurring in about 2 per million population annually.

ATR-101 (Atterocor, Inc., Ann Arbor, MI, USA) is in clinical development for the treatment of adrenocortical carcinoma (ACC). ATR-101 is a selective inhibitor of ACAT1 (acyl coenzyme A:cholesterol acyltransferase). ACAT1 catalyzes cholesterol ester formation and, in the adrenals, is particularly important in creating a reservoir of substrate for steroid biosynthesis. ATR-101 is uniquely distributed to adrenal tissues and inhibition of adrenal ACAT1 by ATR-101 disrupts steroidogenesis and leads to selective apoptosis of steroid producing adrenocortical-derived cells. Similar effects have been seen in the human ACC cell line, H295R. ATR-101 has shown pre-clinical efficacy in H295R xenograft mouse models. ACC is an ultra-rare malignancy, occurring in about 2 per million population annually. ACC is frequently discovered in Stage 4 and the overall disease survival is approximately 17 months. Tumors often overproduce steroids normally produced in the adrenal cortex. Current therapies are toxic, difficult to administer, and poorly effective. Clinical trial information: NCT01898715.

Adrenocortical carcinoma (ACC) generally has poor prognosis. Existing treatments provide limited benefit for most patients with locally advanced or metastatic tumors. We investigated the mechanisms for the cytotoxicity, xenograft suppression and adrenalytic activity of ATR-101 (PD132301-02), a prospective agent for ACC treatment. Oral ATR-101 administration inhibited the establishment and impeded the growth of ACC-derived H295R cell xenografts in mice. ATR-101 induced H295R cell apoptosis in culture and in xenografts. ATR-101 caused mitochondrial hyperpolarization, reactive oxygen release and ATP depletion within hours after exposure, followed by cytochrome c release, caspase-3 activation, and membrane permeabilization. When combined with ATR-101, lipophilic free radical scavengers suppressed the reactive oxygen release, and glycolytic precursors prevented the ATP depletion, abrogating ATR-101 cytotoxicity. ATR-101 directly inhibited F1F0-ATPase activity and suppressed ATP synthesis in mitochondrial fractions. ATR-101 administration to guinea pigs caused oxidized lipofuscin accumulation in the zona fasciculata layer of the adrenal cortex, implicating reactive oxygen release in the adrenalytic effect of ATR-101. These results support the development of ATR-101 and other adrenalytic compounds for the treatment of ACC.

| Company | Millendo Therapeutics Inc. |

| Description | Selective inhibitor of sterol O-acyltransferase 1 (SOAT1; ACAT1) |

| Molecular Target | Sterol O-acyltransferase 1 (SOAT1) (ACAT1) |

PATENT

WO2013142214

https://www.google.co.in/patents/WO2013142214A1?cl=en

PATENT

WO-2016049518

One such promising agent is N-(2,6-bis( 1 -methylethyl)phenyl)-N'-(( 1 -(4-(dimethyl-amino)phenyl)cyclopentyl)methyl)urea hydrochloride ("ATR-101"). The free base form of ATR-101 has the following chemical structure:

The chemical synthesis of ATR-101 has been previously reported by Trivedi et al. (J. Med. Chem. 37: 1652-1659, 1994). This procedure, however, does not provide for ATR-101 in a form suitable for solid-dosing, particularly with regard to capsule or tablet formation, and does not provide for ATR-101 in high purity.

While significant advances have been made in this field, particularly in the context of ATR-101, there remains a substantial need for improved techniques and products for the oral administration of ATR-101 to patients in need thereof, including patients having ACC and/or other disorders or conditions such as Cushing's syndrome and congenital adrenal hyperplasia (CAH).

EXAMPLE 1

SYNTHESIS OF SOLID DRUG FORM OF ATR-101

Step 1 : Preparation of Primary Amine 2 from the Nitrile 1

Tetrahyrofuran (THF) and Compound 1 are charged to a reactor vessel and a lithium aluminum hydride (LAH) solution in THF is added slowly. After the addition, the reaction mixture is warmed to 45°C and stirred until in-process HPLC analysis indicates that the reaction is complete. The reaction mixture is cooled to between 0 and 10°C and aqueous NaOH is added slowly while controlling the temperature to between 0 and 10°C. The mixture is then warmed to between 20 and 25°C and any inorganic salts removed by filtration. The solids are then washed with additional THF.

The filtrate is distilled under vacuum. Acetonitrile (MeCN) is added and the distillation continued to reduce the total volume. H20 is added and the solution is cooled to 20°C, and seeded if necessary. Additional water is added to the slurry and cooled to between 0 and 5°C and filtered. The crystallization vessel and filter cake is washed with MeCN and water (1 :2 mixture) and dried under vacuum between 40 to 45°C to produce Compound 2. Typical yield: 85%.

Step 2: Preparation of ATR-101 Free Base

2,6-Diisopropyl aniline hydrochloride (Compound 3) is converted to the corresponding free base by stirring in a mixture of dichloromethane (DCM) and 10% aqueous NaOH. The organic phase is separated and washed with water. The DCM solution containing the aniline free base is concentrated by distillation.

4-dimethylaminopyridine (DMAP) and DCM are charged to a separate reaction vessel. The mixture is cooled and a solution of di-tert-butyl dicarbonate (Boc20) in DCM is slowly added while the temperature is maintained between 0 and 5°C. The aniline free base solution is then slowly added to the reaction vessel. A complete conversion of aniline to the isocyanate is verified by in-process HPLC analysis.

Compound 2 and MeCN are charged to a separate vessel and this solution is cooled to between 0 and 5°C. The isocyanate intermediate solution

(prepared above) is slowly added while the temperature is maintained between 0 and 5°C, and stirred until in-process HPLC indicates that the reaction is complete.

The reaction mixture is distilled under vacuum, and isopropyl alcohol

(IP A) is added and the distillation is continued. The resulting solution is cooled and seeded, if necessary. After crystallization occurs, water is added and the mixture is cooled to between 0 and 5°C, and filtered. The crystallization vessel and filter cake is washed with isopropanol: water (1 : 1) and the product cake is dried under vacuum to yield ATR-101 as the free base. Typical yield: 89 %

Step 3 : Preparation of Solid Drug Form of ATR- 101

The ATR-101 free base is dissolved in acetone and filtered to remove particulates. Additional acetone is used to rinse the dissolution vessel and filter. Concentrated hydrochloric acid (HCl) is added while maintaining the reaction at room temperature. The resultant slurry is filtered and the cake is washed with acetone. The resulting solid is dried under vacuum between 40 and 45°C to obtain the solid drug form of ATR-101. Typical yield: 70-80 %.

EXAMPLE 2

CHARACTERIZATION OF THE SOLID DRUG FORM OF ATR-101

The solid drug form of ATR-101 was analyzed to fully characterize the material and provide proof of structure.

Elemental Analysis

An elemental (CHN) analysis was conducted, in duplicate, of the solid drug form of ATR-101. The results are summarized in Table 1 and are in agreement with the theoretical values calculated for the molecular ATR-101 drug substance formula of C27H39N3O HCl.

Table 1

Chloride Content

The solid drug form of ATR-101 is prepared as its HCl salt. To confirm the chloride content (and the stoichiometry), the hydrochloride salt was analyzed by Ion Chromatography using a validated method. The w/w% result showed 7.8% chloride present. The theoretical value for a mono hydrochloride salt is 7.7%. The experimental result conforms to the theoretical value for the mono-hydrochloride salt.

Mass Spectrometry

Mass spectrometry studies were conducted in accordance with

USP<736> using an AB Sciex API 2000 LC/MS/MS system. The samples were analyzed by electrospray ionization in positive mode. The base peak observed was 422.3 (M+H-HC1), consistent with the parent compound (see Figure 1). Two minor peaks were observed, at 301.3 and 202.3 (uncharacterized fragments). The combined data of the LC/MS and CFIN results support the molecular formula assignment of C27H39N3O and mass of 421.63 g/mol for the free base and C27H39N3O . HCl (mass of 458.09 g/mol) for the mono hydrochloride salt.

Nuclear Magnetic Resonance (NMR) - 1H NMR

The proton NMR spectrum of the solid drug form of ATR-101 was obtained using a Varian Gemini 400 MHz spectrometer and. The sample was dissolved in CD3OD. The resulting proton NMR spectrum is shown in Figure 2.

Two-Dimensional (2D) NMR

The 2D proton NMR spectrum (COSY) shown in Figure 3 confirmed some of the connectivity expected for the solid drug form of ATR-101. In particular the resonance at 1.2 ppm is strongly correlated to the resonance at 3.1. This correlation together with the splitting pattern observed for the peak at 3.1 strongly suggests an isopropyl moiety. Further, the data from these spectra show a strong correlation between each of the broad peaks at 1.6-2.2 ppm, consistent with a cycloalkyl functionality in which no heteroatoms or other non-alkyl substitution is present.

Carbon 13 NMR (13C NMR)

The 100 MHz 13C NMR spectrum of the solid drug form of ATR-101 was obtained using a Varian Gemini 400 MHz spectrometer. The sample was dissolved in CD3OD. The resulting 13C NMR spectrum is shown in Figure 4. The numbering of the carbon atoms for the analysis of the spectrum is shown below, and the interpretation is shown in Table 2. The observed signals are consistent with the structure of ATR-101.

Table 2

Fourier Transform Infrared Spectroscopy (IR)

Infrared (IR) spectroscopy was performed using the soid drug form of ATR-101. The resulting spectrum, shown in Figure 5, is consistent with the structure of ATR-101 drug substance. The major peak assignments are presented in Table_3.

Table 3

EXAMPLE 3

COMPARISON WITH PRIOR ART SYNTHESIS OF ATR-101 (BY TRIVEDI ETAL.. J. MED. CHEM. 37: 1652-1659, 1994)

ATR-101

In this experiment, 10.6 g of ATR-101 was synthesized according to the above procedure, which corresponds to the the procedure set forth in Trivedi et al., J. Med. Chem. 137: 1652-1659, 1994 (hereinafter referred to as the "Trivedi procedure"). The purity of ATR-101 as made by the Trivedi procedure was found to be 94.9%, compared to a purity of 98.3% for ATR-101 obtained by the procedure of Example 1 and as evaluated in Example 2.

Step 1 : Alkylation of p-nitrophenylacetonitrile

52

The initial alkylation reaction was run on 15.0 g scale and, according to the Trivedi procedure, should have given 15.7 g (79%) of product 52. However, several problems occurred, and the yield was much lower than expected (6.0 g, 30% yield), although the purity by 1H NMR and melting point (actual: 71-72°C, reported: 76°C) seemed good. Approximately half way through the addition of 1 ,4-bromobutane and p- nitrophenylacetonitrile to NaH, a black solid precipitated out of the purple solution causing the stirbar in the flask to skip and jump. The rate of stirring had to be monitored throughout the remainder of the addition to maintain a sluggish and inefficient mixing of the solution.

After stirring at ambient temperature overnight to ensure reaction completion, the reaction was worked-up as the procedure indicated. First, excess ether was removed using air bubbling, and the black solid was isolated by filtration. Diethyl ether was then added until all of the solids dissolved to give a clear black solution. However, upon washing the ether solution with 2N HC1, a black amorphous solid precipitated from the solution. There was no note of this black solid in the Trivedi procedure, so the work-up was continued without modification. The black solids ended up in the aqueous washes, or stuck to the seperatory funnel. The remainder of the work-up proceeded as expected, and the hot hexanes extraction of the crude solid resulted in light pink planar crystals.

The procedure was repeated with two changes thought to be responsible for the low yield: the anhydrous solvent (from the bottle) was sieve dried to remove trace water, and the stir bar was replaced with a mechanical stirrer to ensure more even mixing of the solution. The procedure was re-run on 10 g scale, which should have yielded 10.5 g of compound 52. However, despite the changes to the procedure, the resulting product and yield was nearly identical to the first run (4.5 g, 34% yield, 71-72°C melting point).

In an attempt to determine where the bulk of material ended up, the aqueous layer from this reaction was re-extracted with diethyl ether, but only resulted in trace amounts of material. The black solids that formed during the work-up were isolated by filtration, and an NMR was taken of the material. The NMR showed peaks corresponding to compound 52. Presumably, this amorphous black solid that resulted after HC1 formation is the main source of lost material, as there appeared to be several grams of it.

Ste 2: Reduction of Nitro Compound

The conversion of nitro compound 52 to the dimethyl amine 53 was done over two steps: palladium catalyzed hydrogenation of the nitro compound to give the free amine 52b, followed by imine formation & reduction to the dimethylamine 53.

An exploratory small scale reaction was run, using 1/10th of the available material (1.0 g compound 52). The reduction of the nitro compound on the 1 gram scale was very rapid, with hydrogen consumption ceasing after 3-4 hours. A crude NMR of an aliquot of the reaction mixture showed very clean amine (52b). The formaldehyde was added, as well as additional Pd/C, and the hydrogenation was continued. The hydrogen was not consumed as quickly for the imine reduction, and the reaction was still progressing when the vessel was pressurized to 55 psi and left shaking overnight (ca. 16h).

After 16 hours, the pressure in the flask had dropped to 30 psi, indicating that the hydrogenation was still progressing overnight. An aliquot NMR confirmed that the reaction had not proceeded to completion.

On large scale, the nitro reduction proceeded very smoothly, consuming hydrogen at a very rapid rate, and going to completion again within 3-4 hours. The reactor was pressurized to 55 psi and shaken overnight, as indicated in the original procedure, before more Pd/C was added, followed by formaldehyde. Hydrogen consumption was again observed to be very sluggish, so the valve to the hydrogen tank was left open to the vessel, and the reaction was shaken for 24 hours.

After 24 hours of shaking, the valve to the vessel was closed, and a drop of 5 psi was observed over 1 hour, indicating that the reaction had not progressed to completion. TLC also showed several polar products, suggesting that the reaction was only ca. 50% complete. The hydrogenation vessel was pressurized to 55 psi with hydrogen, and the valve again left open for an additional 24 hours of hydrogenation.

After 24 hours, the reaction stopped consuming hydrogen, and the vessel was purged and the contents filtered to remove the palladium catalyst. The work-up was performed similarly to the small scale, and the two reactions were combined prior to purification by column chromatography, giving 5.7g (57.5% yield) of the desired dimethylamine product 53.

Step 3 : Reduction of C ano Compound

A small scale RaNi hydrogenation was done and the test reaction went smoothly. Hydrogen consumption was rapid, and the reaction appeared complete after approximately 2 hours. The consumption of hydrogen had ceased, and TLC indicated that there was no compound 53 remaining. After filtration to remove the Raney Nickel, the reaction completion was confirmed by aliquot NMR.

The remaining material was subjected to reduction using the same conditions, and hydrogen consumption and TLC analysis again indicated reaction completion after 2 hours. The material was filtered and combined with the smaller scale reaction material. After concentration to dryness, the crude yield was found to be 5.5 g (96.5% yield), which was very close to the reported yield (99%>).

Step 4: Formation of Urea Com ound

Urea formation is a straightforward procedure, and the small scale test reaction with the amine 54 (500 mg) being combined with 1.0 equivalent of the

isocyanate in 20 parts ethyl acetate. After stirring for 16 hours, the solution was concentrated to dryness to give a white solid. Crude 1H NMR of the solid confirmed that the spectra matched the reported spectra in the Trivedi procedure.

The remaining material was carried forward to ATR-101 freebase without difficulty, and the lots of product were combined. In an effort to remove the residual ethyl acetate, the solids were dissolved in 10 mL of toluene, followed by concentration under reduced pressure. After drying on high- vacuum, ATR-101 freebase was isolated as a sticky white foam (10.6 g, 99% yield). The 1H NMR of the final product showed trace toluene even after extended drying, and the material was moved on to the HC1 salt formation.

The melting point of the solid was later taken and found to be surprisingly low (50-56°C, expected: 132-133°C). The nature of the solid (oily foam) made the determination of the melting point difficult, but it was judged to be completely melted above 60°C.

Step 5: Formation of HC1 Salt

To the ATR-101 freebase in toluene was added 37% HC1, and a gummy white solid precipitated out immediately. The solution was dried by Dean-Stark apparatus over approximately 3 hours with vigorous stirring and heating (bath temp: 160°C). After drying, the solution was cooled and the fine crystalline solid was isolated by filtration and washed with acetone and diethyl ether. The product ATR-101 was dried until a constant weight was achieved (10.6 g, 92% yield) and fully characterized.

Figure 1 is the LC/MS Mass spectrum of the solid drug form of ATR- 101.

Figure 2 is the proton NMR spectrum of the solid drug form of ATR- 101.

Figure 3 is the 2-D 1H NMR spectrum (COSY) of the solid drug form of ATR-101.

Figure 4 is the 13C NMR spectrum of of the solid drug form of ATR- 101.

Figure 5 is the FT-IR spectrum the solid drug form of ATR-101.

Paper

(J. Med. Chem. 37: 1652-1659, 1994

http://pubs.acs.org/doi/abs/10.1021/jm00037a016

| Patent ID | Date | Patent Title |

|---|---|---|

| EP0474733 | 1994-08-31 | ANTIHYPERLIPIDEMIC AND ANTIATHEROSCLEROTIC UREA COMPOUNDS. |

| WO9015048 | 1990-12-13 | ANTIHYPERLIPIDEMIC AND ANTIATHEROSCLEROTIC UREA COMPOUNDS |

| Patent ID | Date | Patent Title |

|---|---|---|

| US2015087649 | 2015-03-26 | TREATING DISORDERS ASSOCIATED WITH ABERRANT ADRENOCORTICAL CELL BEHAVIOR |

| US2013267550 | 2013-10-10 | Compounds and Methods for Treating Aberrant Adrenocartical Cell Disorders |

| EP0858336 | 2006-12-20 | METHOD AND PHARMACEUTICAL COMPOSITION FOR REGULATING LIPID CONCENTRATION |

| US2005234124 | 2005-10-20 | Carboxyalkylether-ACAT inhibitor combinations |

| US2004072903 | 2004-04-15 | Carboxyalkylether-acat inhibitors combinations |

| US6143755 | 2000-11-07 | Pharmaceutical methods of treatment with ACAT inhibitors and HMG-CoA reductase inhibitors |

| US6124309 | 2000-09-26 | Method and pharmaceutical composition for regulating lipid concentration |

| US6093719 | 2000-07-25 | Method and pharmaceutical composition for regulating lipid concentration |

| WO9716184 | 1997-05-09 | METHOD AND PHARMACEUTICAL COMPOSITION FOR REGULATING LIPID CONCENTRATION |

| EP0474733 | 1994-08-31 | ANTIHYPERLIPIDEMIC AND ANTIATHEROSCLEROTIC UREA COMPOUNDS. |

References

1: Wolfgang GH, MacDonald JR, Vernetti LA, Pegg DG, Robertson DG. Biochemical alterations in guinea pig adrenal cortex following administration of PD 132301-2, an inhibitor of acyl-CoA:cholesterol acyltransferase. Life Sci. 1995 Feb 17;56(13):1089-93. PubMed PMID: 9001442.2: Saxena U, Ferguson E, Newton RS. Acyl-coenzyme A:cholesterol-acyltransferase (ACAT) inhibitors modulate monocyte adhesion to aortic endothelial cells. Atherosclerosis. 1995 Jan 6;112(1):7-17. PubMed PMID: 7772069.

3: Reindel JF, Dominick MA, Bocan TM, Gough AW, McGuire EJ. Toxicologic effects of a novel acyl-CoA:cholesterol acyltransferase inhibitor in cynomolgus monkeys. Toxicol Pathol. 1994 Sep-Oct;22(5):510-8. PubMed PMID: 7899779.

4: Krause BR, Black A, Bousley R, Essenburg A, Cornicelli J, Holmes A, Homan R, Kieft K, Sekerke C, Shaw-Hes MK, et al. Divergent pharmacologic activities of PD 132301-2 and CL 277,082, urea inhibitors of acyl-CoA:cholesterol acyltransferase. J Pharmacol Exp Ther. 1993 Nov;267(2):734-43. PubMed PMID: 8246149.

5: Dominick MA, McGuire EJ, Reindel JF, Bobrowski WF, Bocan TM, Gough AW. Subacute toxicity of a novel inhibitor of acyl-CoA: cholesterol acyltransferase in beagle dogs. Fundam Appl Toxicol. 1993 Feb;20(2):217-24. PubMed PMID: 8383621.

6: Dominick MA, Bobrowski WA, MacDonald JR, Gough AW. Morphogenesis of a zone-specific adrenocortical cytotoxicity in guinea pigs administered PD 132301-2, an inhibitor of acyl-CoA:cholesterol acyltransferase. Toxicol Pathol. 1993;21(1):54-62. PubMed PMID: 8397438.

///////ATR 101, 133825-81-7, ATR-101 HCl, 133825-80-6, Millendo Therapeutics, ACAT1 inhibitor, treating adrenal cancers, adrenocortical cancer, congenital adrenal hyperplasia, Atterocor, Inc., Ann Arbor, MI, USA

O=C(NCC1(C2=CC=C(N(C)C)C=C2)CCCC1)NC3=C(C(C)C)C=CC=C3C(C)C.[H]Cl

No comments:

Post a Comment